The strength of Malaysia's die-casting business is its capacity to make high-precision products with incredible consistency. The companies use the latest equipment and advanced technology to satisfy the stringent demands of various industries. From parts for engines used in the automotive sector to the intricate electronic components used in gadgets, Malaysian die-casting firms deliver products that meet international specifications. The versatility of die casting allows manufacturers to produce parts with complex geometries, ensuring the industries that depend on intricate designs can benefit from affordable and durable solutions. This capability underscores the importance of die casting in Malaysia's industrial system.

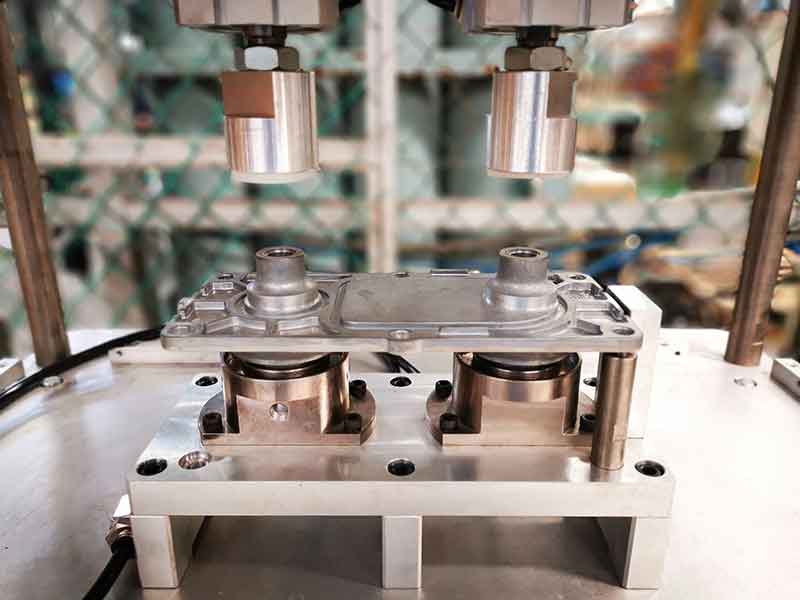

Innovation is an important driving force in die casting in Malaysia and the manufacturers constantly implement new technology to improve the efficiency of their operations. Automation has transformed die casting processes, using robots that ensure accuracy and uniformity in the manufacturing. Modern simulation tools are utilized to enhance mold designs, reducing material production waste, and increasing the quality of product. Many Malaysian businesses have also taken on Industry 4.0 practices, integrating IoT enabled devices as well as analysis of data into processes. This technological advance does not just enhance efficiency but also help producers to respond to the ever-changing requirements of their customers. Through staying on the forefront of technological advancement, Malaysia's casting industry remains competitive on a global scale.

Technology and innovation are changing the industry of die casting in Malaysia and driving improvement in efficiency, quality, as well as sustainability. Modern manufacturing methods, such as vacuum die casting, and multi-slide technology are being used to boost the manufacturing of intricate components. Robotics and automation are playing an increasingly prominent role in reducing costs of production and increasing the consistency of the quality. These technological advancements not only enhance Malaysia's manufacturing capabilities but also position the country as a leader in precision engineering. With the investment in the research and development process, Malaysian die casting firms remain ahead of the game in an increasingly competitive world market. To generate more details please website link

Sustainability is an emerging focus in Malaysia's Malaysian manufacturing industry of die casting in which companies are working to align their practices with global environmental standards. Initiatives to cut down on energy usage as well as reduce waste production and make use of recycled materials are gaining traction. In the adoption of closed loop methods, which reuse heat and materials within the production process, exemplifies the industry's dedication to maximizing efficiency of resources. The initiatives do not just reduce environmental impact but also contribute to cost savings, making sustainability a win both for businesses as well as the environment. Through a focus on eco-friendly manufacturing practices, Malaysia's industry has established its self as a responsible, progressive player in the global market.

Die casting is a cornerstone of the manufacturing industry in Malaysia, aiding in innovation, efficiency and sustainability. Its versatility and precision are essential for a broad range of industries, ranging from aerospace and automotive to consumer electronics. Its focus is on technology advancement, efficient labor force, and sustainability, Malaysia has positioned itself as a leading player in the world die casting market. In a time when the demand for premium precisely engineered and precision-engineered products increases, the Malaysian manufacturing industry is poised to play an even greater role in defining the future of manufacturing by providing cutting-edge solutions to are able to meet the requirements of an ever-changing global.